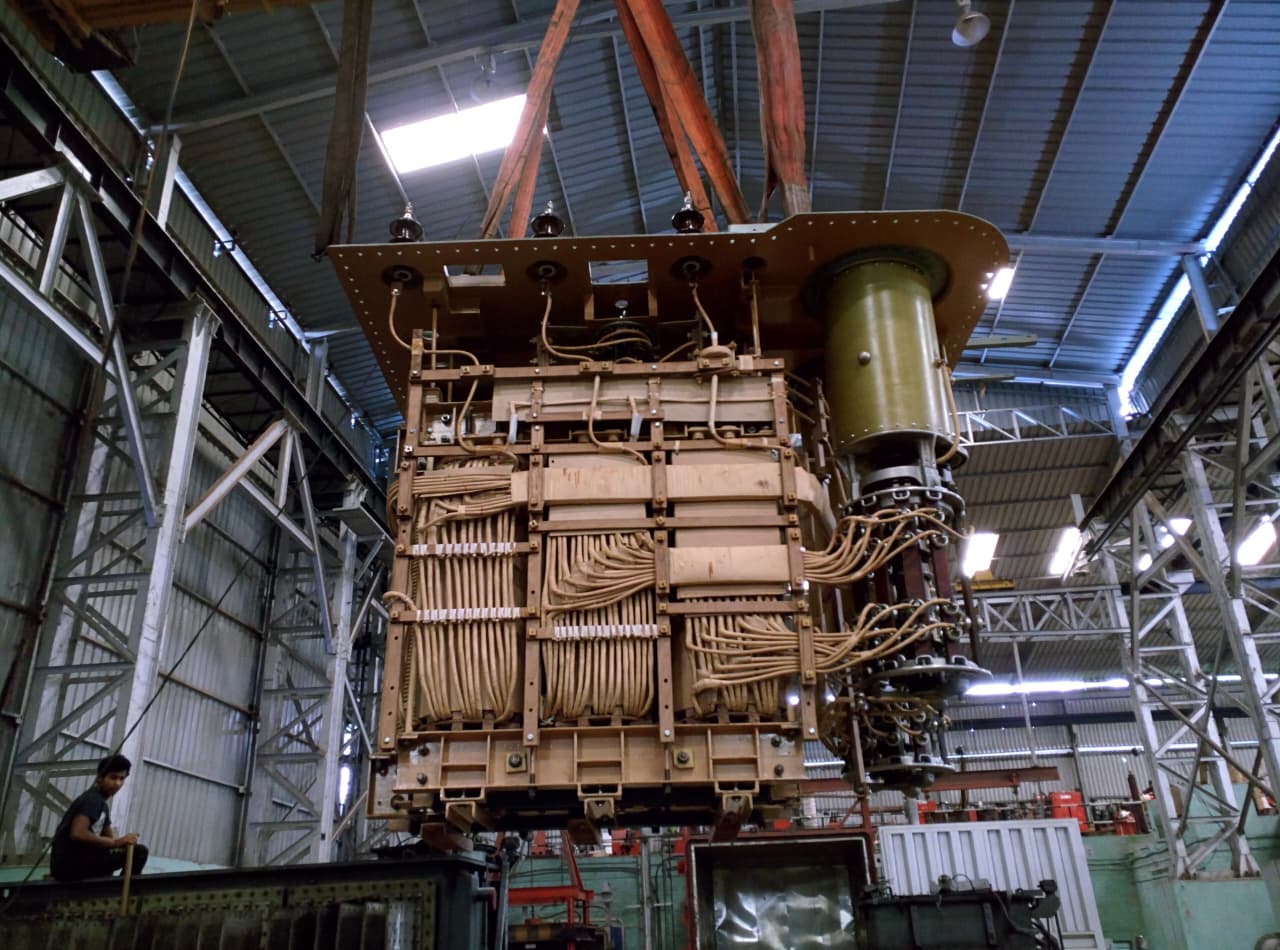

Furnace Transformer

Furnace Transformer

Century Transformers Pvt. Ltd. specializes in manufacturing high-performance Furnace Transformers designed to meet the demanding requirements of electric arc, induction, and ladle furnaces. Built with superior-grade materials and precision engineering, our transformers ensure high current output, voltage stability, and excellent thermal endurance. Each unit is engineered for efficient energy transfer, low losses, and long operational life, even under extreme heat and load conditions. Manufactured under strict ISO 9001:2008 quality standards, our furnace transformers are ideal for steel, foundry, and metallurgical industries, offering safe, reliable, and efficient power solutions for continuous heavy-duty operation.

Furnace Transformers

Century Transformers Pvt. Ltd. offers a complete range of Furnace Transformers designed for steel, foundry, and metallurgical industries. Built for durability and precision, our transformers deliver exceptional performance, energy efficiency, and reliability under demanding thermal and electrical conditions.

Furnace Transformer (up to 30 MVA)

Designed for high-capacity industrial operations, ensuring stable power delivery, reduced losses, and long operational life even in extreme environments.

Arc Furnace Transformer

Engineered for electric arc furnaces, providing reliable high-current output and precise voltage regulation for efficient steel melting and refining processes.

Submerged Arc Furnace Transformer

Designed to power submerged arc furnaces used in ferroalloy and silicon production, offering consistent performance and superior thermal stability.

Ladle Furnace Transformer

Provides precise voltage control and efficient heating during secondary steel refining, ensuring high-quality end products and energy-efficient operation.

Induction Furnace Transformer

Specially developed for induction furnaces, delivering controlled power and excellent efficiency for melting non-ferrous and ferrous metals.

DC Arc Furnace Transformer

Converts AC to DC for modern furnace systems, minimizing electrode wear and ensuring uniform melting with superior energy efficiency.

Features of Furnace Transformers

High Current Capability: Designed to handle extremely high secondary currents essential for melting and heating applications.

Robust Construction: Heavy-duty design with reinforced mechanical strength to withstand frequent short circuits and thermal stresses.

Efficient Cooling Systems: Available with ONAN, ONAF, OFWF, and water-cooled options for effective heat dissipation and continuous operation.

Voltage Regulation: Multi-tap design provides precise voltage control for stable furnace performance under fluctuating load conditions.

Superior Materials: Built using high-grade CRGO steel cores and electrolytic copper or aluminum windings for maximum efficiency and durability.

Reduced Power Losses: Engineered for low losses and high efficiency, optimizing energy usage and lowering operational costs.

Enhanced Safety Features: Integrated with Buchholz relay, pressure relief devices, temperature indicators, and oil-level gauges for safe and reliable operation.

Custom Design Options: Transformers can be customized for furnace type, duty cycle, cooling method, and output requirements.

High Thermal Endurance: Insulation system designed to perform efficiently under high-temperature and high-load conditions.

Compliance: Fully compliant with IS, IEC, and international furnace transformer standards for consistent performance and reliability.